-

Excavator Hydraulic Pump

-

Excavator Main Control Valve

-

Excavator Final Drive

-

Excavator Swing Gearbox

-

Hydraulic Fan Pump

-

Hydraulic Pump Parts

-

KAWASAK Hydraulic Pump

-

Excavator Travel Motor

-

Hydraulic Repair Kit

-

Hydraulic Overflow Valve

-

Hydraulic Electromagnetic Valve

-

Excavator Pilot Pump

-

Excavator Engine

-

JoseI like this company. They are professional and friendly. Excellent service and friendly advice, fast delivery. Very good price. I want to order again when I need it.

JoseI like this company. They are professional and friendly. Excellent service and friendly advice, fast delivery. Very good price. I want to order again when I need it. -

Lauren MelvilleExcellent service, quality product.

Lauren MelvilleExcellent service, quality product. -

Санёк НижегородскийМэргэжлийн үйлчилгээ, хурдан шуурхай хүргэлт.

Санёк НижегородскийМэргэжлийн үйлчилгээ, хурдан шуурхай хүргэлт. -

Erdenetumur Kampanaa pleasant shopping

Erdenetumur Kampanaa pleasant shopping

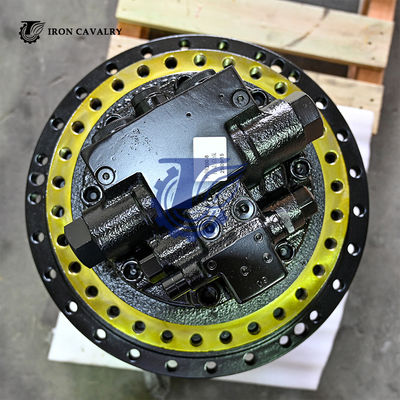

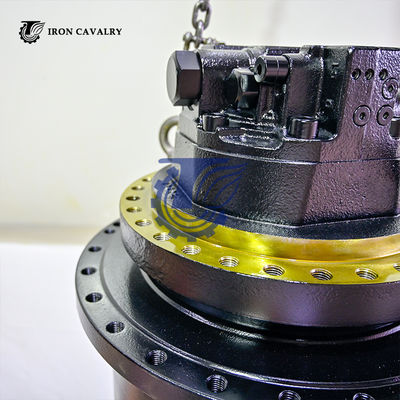

KOBELCO SK200-8 210-8 250-8 Excavator Final Drive Assembly Parts GM38VB

| Product Name | KOBELCO SK200-8 Excavator Final Drive Assembly High Quality Parts GM38VB | Applicable Machine Model: | KOBELCO SK200-8 Excavator Final Drive Assembly Parts GM38VB |

|---|---|---|---|

| Applicable Industries: | Mechanical Repair Shops, Retail, Construction, Energy, Mining | Category | Final Drive |

| Condition: | NEW/REBUILT | Brand | IRON CAVALRY |

| Highlight | KOBELCO excavator final drive assembly,SK200-8 excavator hydraulic parts,GM38VB final drive with warranty |

||

KOBELCO SK200-8 Excavator Final Drive Assembly High Quality Parts GM38VB

| Model | KOBELCO SK200-8 Final Drive Assembly GM38VB |

|---|---|

| Part Number | GM38VB SK200-8 |

| Brand | IRON CAVALRY |

| Place of Origin | CHINA |

| Condition | Original & OEM |

| Warranty | 12 months |

| MOQ | 1 pcs |

| Production Capacity | 1000pcs /Month |

| Standard or Nonstandard | Standard |

| Payment Term | L/C, T/T, Western Union, Tradeassurance |

| Delivery Time | 3-7 days (depend on order) |

| Means of Transport | By Sea, Air or DHL/FEDEX/TNT/EMS |

| Guarantee | We will check and send detailed pictures to buyers for confirmation |

In excavators (such as the Kobelco SK200-8), the travel assembly or travel motor primarily serves the following functions:

- Converting hydraulic system output to drive track movement: When the operator pushes the excavator, the hydraulic pump sends hydraulic oil to the motor. The motor rotates, driving the reduction gear, which then outputs the power to the drive gears, ultimately moving the wheels/track chains. This enables the excavator to move forward, backward, turn, and stop.

- Handling the drive requirements of high loads and low speeds with high torque: Crawler excavators require strong traction and torsional resistance in earthmoving, mining, crushing, and slope applications. The travel assembly must ensure sufficient torque and reliable durability. The final reduction gear set converts the motor's high-speed rotation to a lower speed, higher torque output suitable for track drive.

- Collaborating with the chassis structure to ensure stability and mobility: During track movement and turning, the travel assembly must withstand the combined stresses from the machine body, engineering loads, and ground reaction forces. It is a key component of the tracked chassis system. If this component fails, it will cause slow movement, deviation, slippage, or even complete inability to move, severely affecting the machine's operational capabilities.

Strategically located in Guangzhou's Huangpu District, approximately an hour from Baiyun International Airport, Tieqi has been a dedicated specialist in engineering machinery hydraulics for nearly 15 years.

Driven by our core values of "Pragmatism and Progress," we are committed to delivering practical solutions and upholding our responsibilities. This principle-driven approach defines all our operations and client partnerships.

In China's excavator hydraulic assembly sector, our efficient execution and rigorous approach to manufacturing every product to meet over 95% of original performance specifications have built widespread trust. This has made us a destination for industry peers and clients seeking knowledge and reliable supply, and we take pride in our role of continuously elevating production standards in China.

We are proud to set the standard for hydraulic manufacturing in China, a commitment recognized by our global clientele in the mining, construction, and trading sectors. We invite you to visit our Guangzhou facility to evaluate our quality processes firsthand.

Our capability is backed by a ready inventory of over 500 assembly types, providing access to more than 6,000 different parts. Hydraulic pump, control valve, travel, and swing assemblies are our core products, with a distinct advantage in large mining excavator components and hard-to-find items.

Our 4,000-square-meter factory in Guangzhou is equipped for professional manufacturing, precision assembly, rigorous testing, and quality certification, ensuring reliable performance and timely delivery for every order.

By integrating top-tier Chinese hydraulic brands and supply chains, we provide cost-effective, convenient, and scalable one-stop solutions tailored to diverse machinery and operational needs. Our ability to expertly meet complex client requirements remains a cornerstone of our service.

For large items, we use sturdy plywood crates secured with metal fasteners for added stability. Inside, the products are cushioned with bubble wrap and secured with wooden braces, while special attention is given to protecting vulnerable parts. Externally, the crates are reinforced with high-strength PET plastic strapping and wrapped in highly waterproof black film. All these measures are taken to ensure that the products reach our customers safely and securely.

- One-stop solution provider for all your hydraulic component needs

- High-quality products at competitive prices

- Exceptional customer service that makes you feel at home

- Large inventory, short delivery times, and long warranty periods

- Professional expertise with accurate part number identification for excavator components